Wall and Facade Elements

Machine Equipment for the Production of Concrete Elements

We offer a large selection from single machines to complete, fully automatic production plants, tailor-made and customized solutions for all areas of element production

- Circulating systems

- Stationary tables

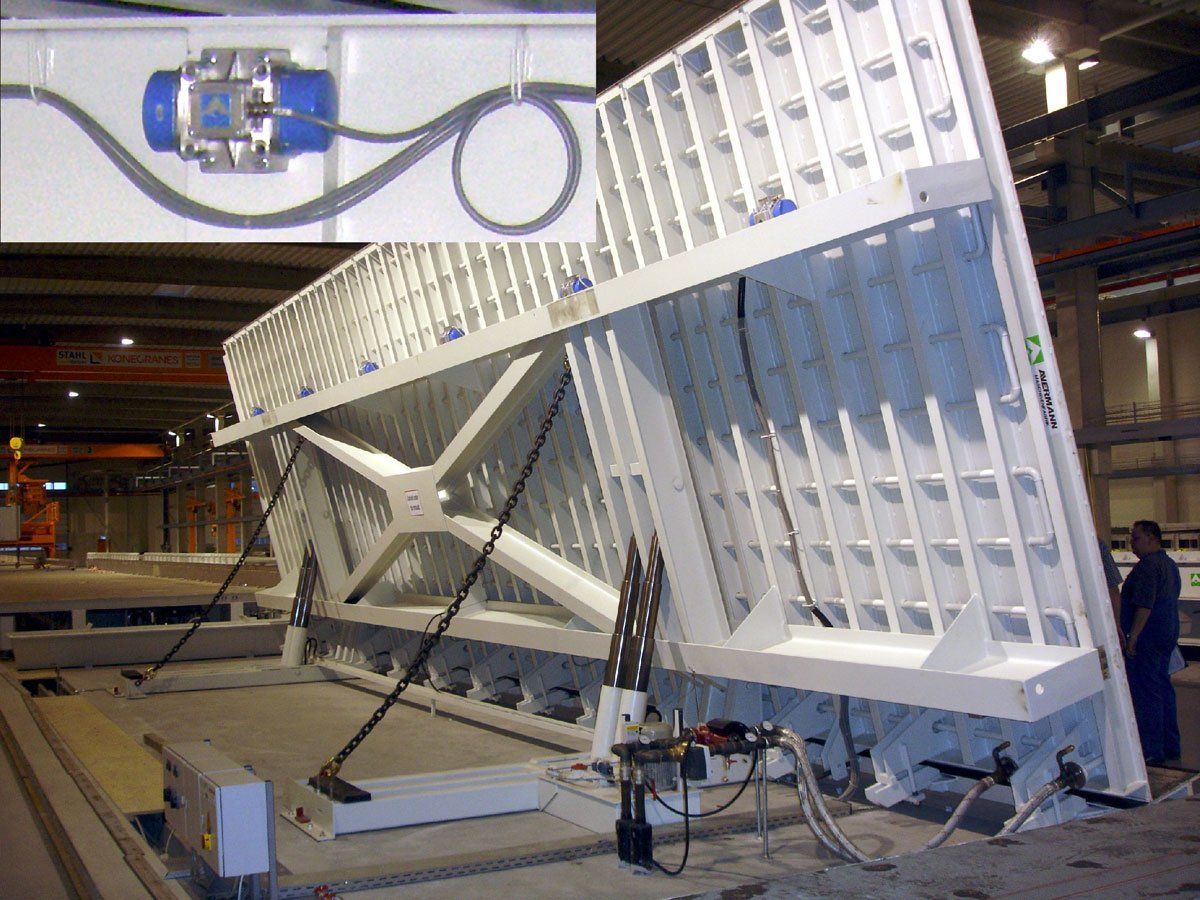

- Tilting tables

- Pallets

- Plotter

- Concrete spreader

- Scraping

- Concrete compaction / vibration

- Smoothing device

- Oiling

- Combination machines

- Shell casting

- Transport

CPT's highly competent partner Avermann Betonfertigteiltechnik GmbH & Co. KG www.avermann.de has been manufacturing high-quality machines and equipment for wall, facade, deck elements, etc. for the concrete element industry since the 1960s, based on a desire to offer competitive and efficient solutions.

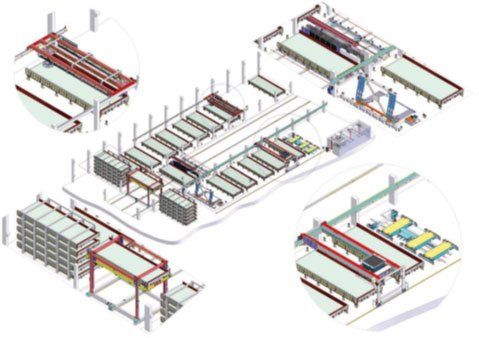

Example of an efficient element production system with CTS Central-Transport-System.

This production plant for wall and facades consists of a number of workstations with movable pallets, which are transported with the CTS system. The system is distinguished by its flexibility, as the time consumption of the individual element is not decisive for the operation of the system.

- Flexible and specialized workstations

- Simplified delivery of materials

- Shutterings at workstations

- Variable processing times create highly flexible production

- Optimized curing technology

- High flexibility with optimized transport

We are Ready to Assist you

Pallets - for rotation system for production of wall, facade elements and deck elements. Delivered in all sizes and designs as needed.

Folding pallets:

- Stationary production equipment for the production of double wall elements

- Cost-effective stand-alone solutions for small and medium-sized productions

- Space-saving construction