Deck and Slab Elements

CPT offers an optimal solution for the manufacture of concrete slab elements.

In each case, the customer's needs are analyzed, and on that basis an optimal logistic is prepared from design and planning to production, storage and transport - in other words, a complete turnkey solution can be offered.

The product range is wide:

- Extruders

- Hollow core benches

- Slipform machines

- Concrete saws

- Bed cleaners

- Drilling systems

- Transport systems

- Wire and clamping equipment

- Laser-driven plotter

- Software, planning system

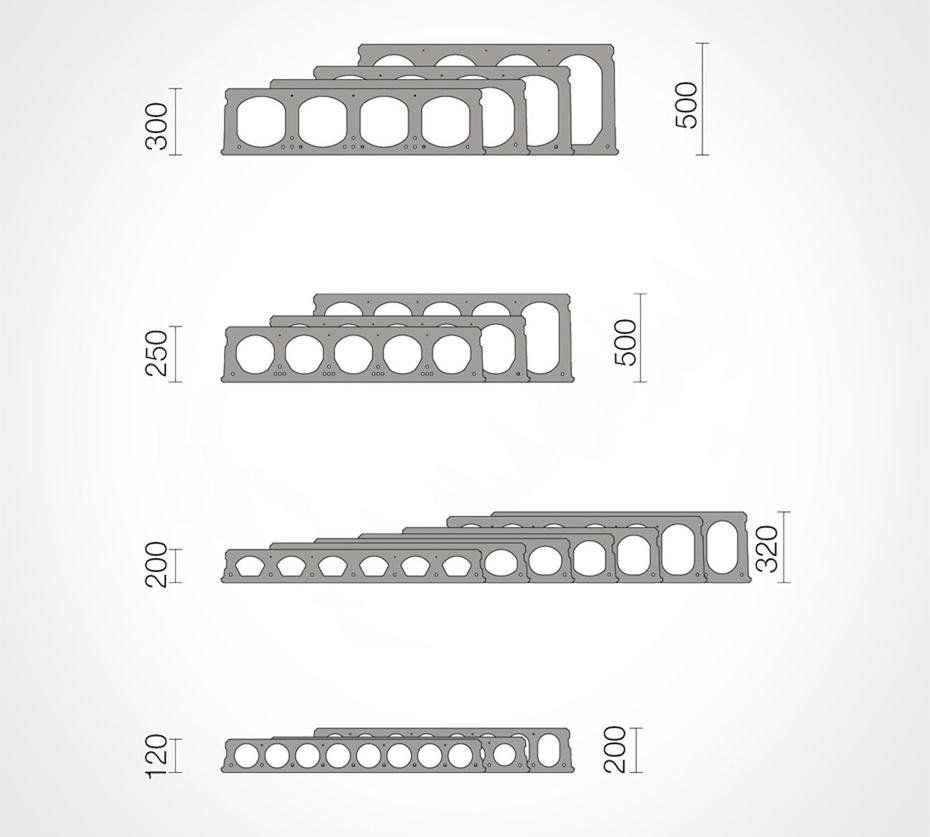

Holllow core:

- Flexible production of hollow cores 120 - 500 mm

- Fast mould change

- Effective compaction = cement savings

- Low costs for service and maintenance

An Extruder is a machine designed for the production of hollow cores on a high technological level with operator-friendly properties.

The S-Liner allows you to produce hollow core slabs, foundation piles, lattice girders and solid floors, T-beams, channels, gutters and even hollow core slabs with insulation and integrated heating and cooling systems.

Depending on the type of element you need, this is the right machine.

Technical data:

| Machine type: | Production level (from - to) |

|---|---|

| S-Liner® T30 | 6 – 30 cm |

| S-Liner® T40 | 15 – 40 cm |

| S-Liner® T50 | 20 – 50 cm |

Each machine type can be configured for a track width of 1.2 meter to 1.5 meter or 2.4 meter.

The right-angle saw RAS allows you to cut at right angles of the cured concrete elements on the production bed to the required plate length. Diamond saw blades with a diameter of 900, 1,100 and 1,300 mm are used for a pallet height of 30 cm, 40 cm and 50 cm.

The MAS multi-angle saw is used to reduce the cured concrete elements to the required length. A range of cuts are possible - 0 degree or 180 degree cuts, plus diagonal cuts from 90 to 0 degrees and from 90 to 180 degrees. The saw speed is set automatically by the saw motor's electronic power control.