Reinforcement from Coils

- Mesh Welding Machines, Automatic Bending

Flexible and cost-efficient production of tailor-made reinforcement mesh from coils

Since 1970 CPT's partner Progress Maschinen & Automation www.progress-m.com has developed and manufactured production equipment for processing reinforcing steel.

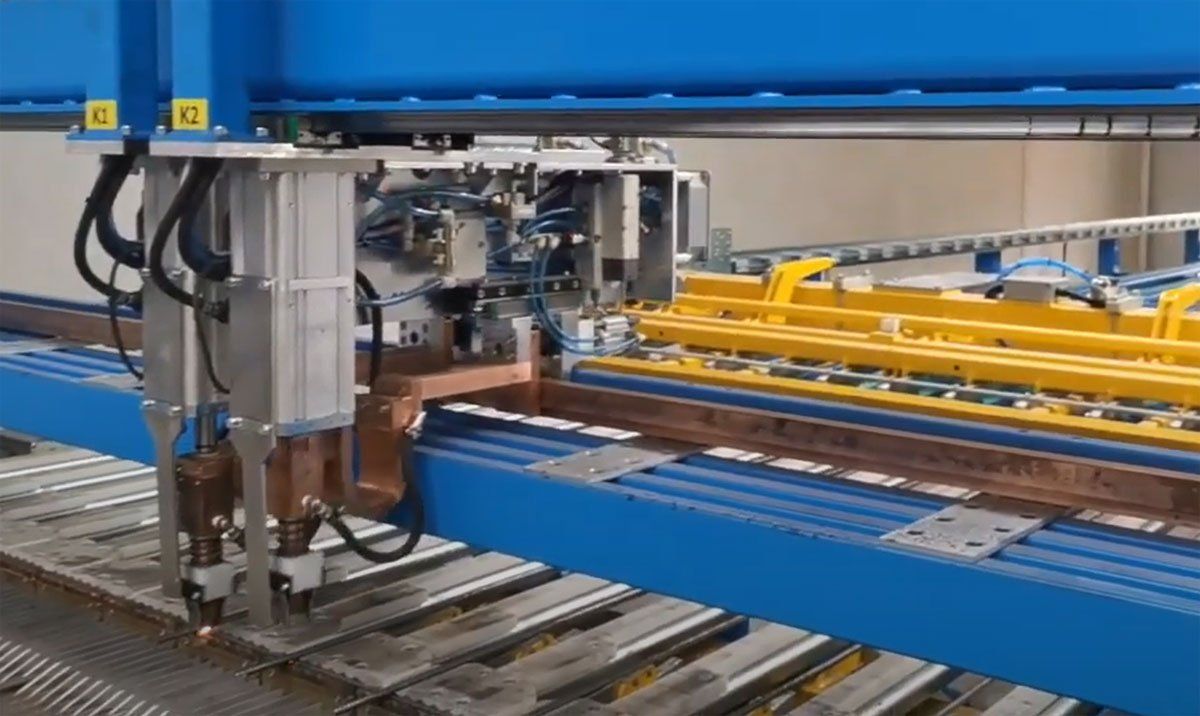

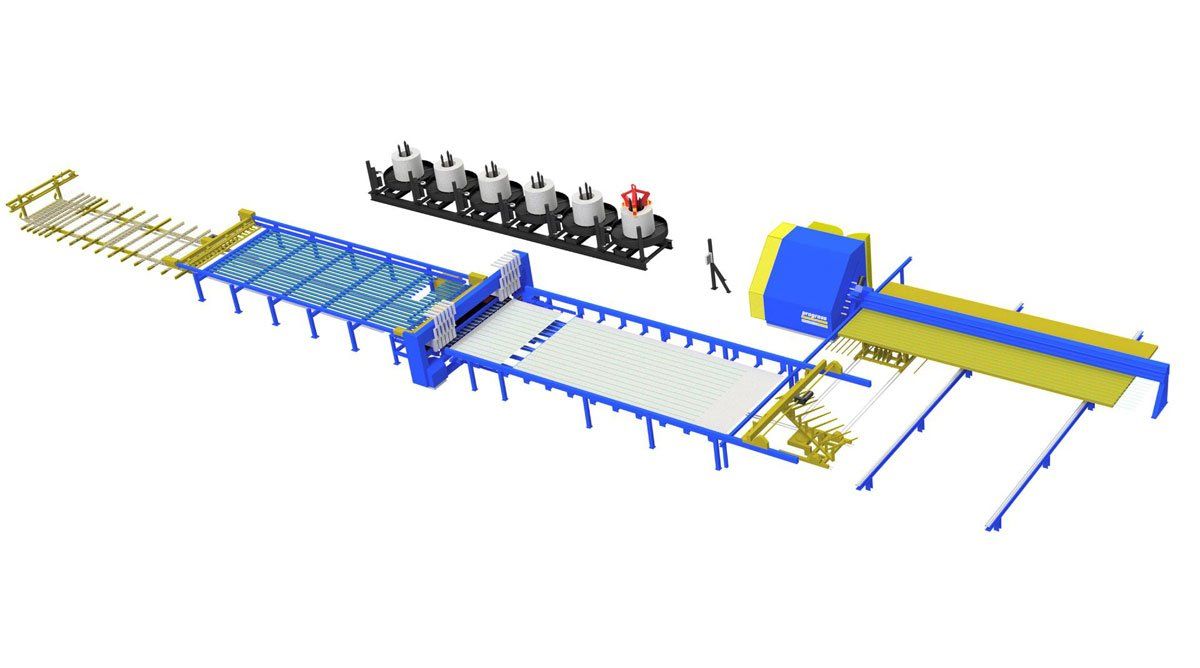

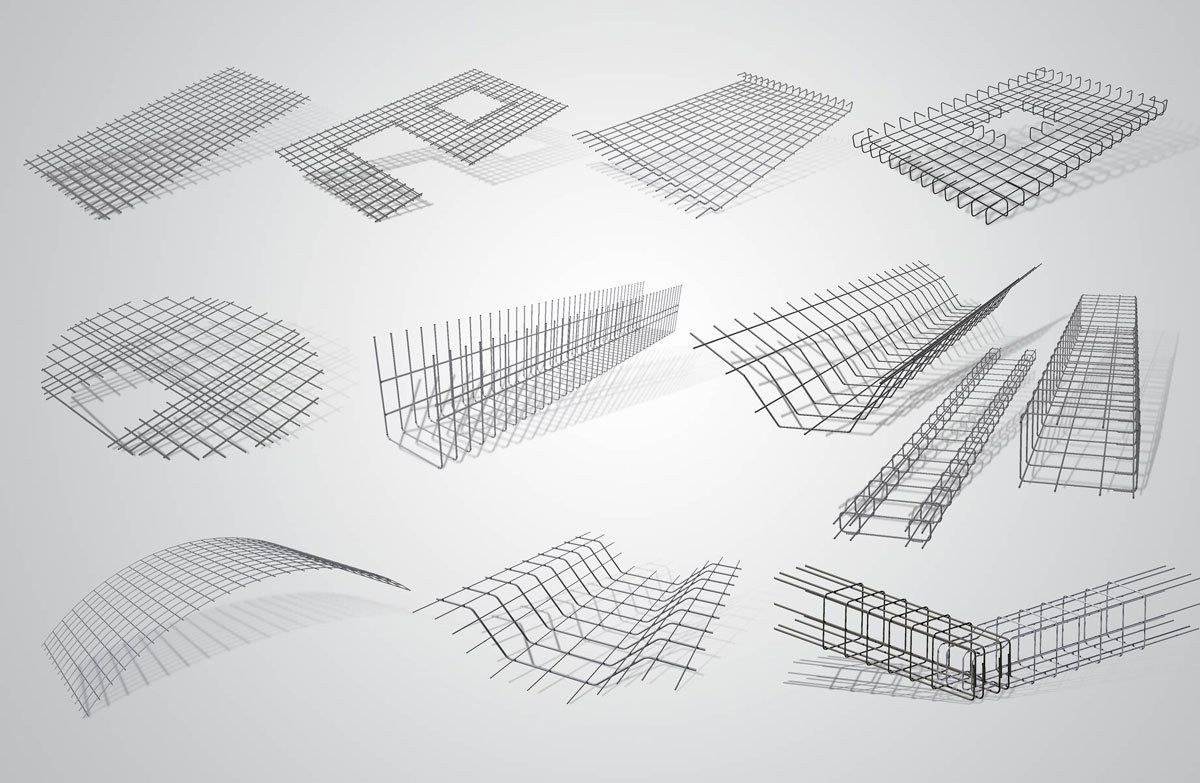

Modern automation technology makes it possible to weld reinforcement meshes fully flexibly in terms of dimensions, mesh size, wire diameter and wire placement, as well as recesses for doors and windows. This makes the machine unique for the production of reinforcement mesh for element production. Once the element is drawn and constructed, the file is automatically transferred to the machine, which checks if the mesh can be produced. The file is then added to the order queue and can be produced "just-in-time" or the day before the element is to be cast.

Quick payback on investment

The great advantages of "in-house" mesh production are that the mesh can be produced just-in-time, the stock can be minimized, and there is no waste when the mesh is produced for the element with recesses for doors and windows. Labour costs are largely reduced, as the mesh needs no adaptation. The most important saving is that the mesh can be manufactured with the wire diameter and positioning that provides the greatest possible strength exactly where the need is.

M-System Smartmesh

Efficiency and simplicity are caracteristic of the M-System Smart Mesh.

This mesh welding system stands out with its low energy and space requirements as well as its low investment costs. The machine straightens and welds the reinforcement mesh directly from coils. This guarantees the high quality of the product. In this respect, M-System SmartMesh is particularly suitable for element productions with smaller production volumes.

We are Ready to Assist you

M-System BlueMesh

This mesh welding system is equipped with 6 welding heads and covers the capacity needs of most element productions. Low energy and space requirements ensure a possible installation in the existing factory. Like the M-System Evolution, it straightens and welds the reinforcement mesh from coils.

| Distance, longitudinal thread | Fixed distance 50 mm, 25 mm or arbitrary distance |

|---|---|

| Distance, transverse wire | Arbitrary distance |

| Number of welding heads | 6 - 9 - 12 (other specifications on request) |

| Diameter longitudinal and transverse wire | 6 - 16 mm (4 - 20 mm on request) |

| Connection power | from 100 KVA |

| Standard mesh dimensions | Min. 0.5 mx 0.5 m Max. 4.5 mx 12 m (other specifications on request) |

M-System Evolution

M-system Evolution is the advanced mesh welding machine. The 9-12 welding heads together with the MSR straightening unit ensure a fast and accurate straightening process of the wire from coils to finished mesh. It has a flexibility and capacity that covers the needs of even very large element productions.

M-System PowerMesh

The high-performance M-System PowerMesh mesh welding system is designed for reinforcing mesh manufacturers. Innovative technical solutions ensure high production quality. The number of welding heads can be adjusted to the desired performance.

The newly developed M-System PowerMesh HS is configured for maximum production performance. The high-speed model is also extremely flexible. The wire diameter changes automatically, the mesh size can be set individually, and the machine can also produce small batch sizes.

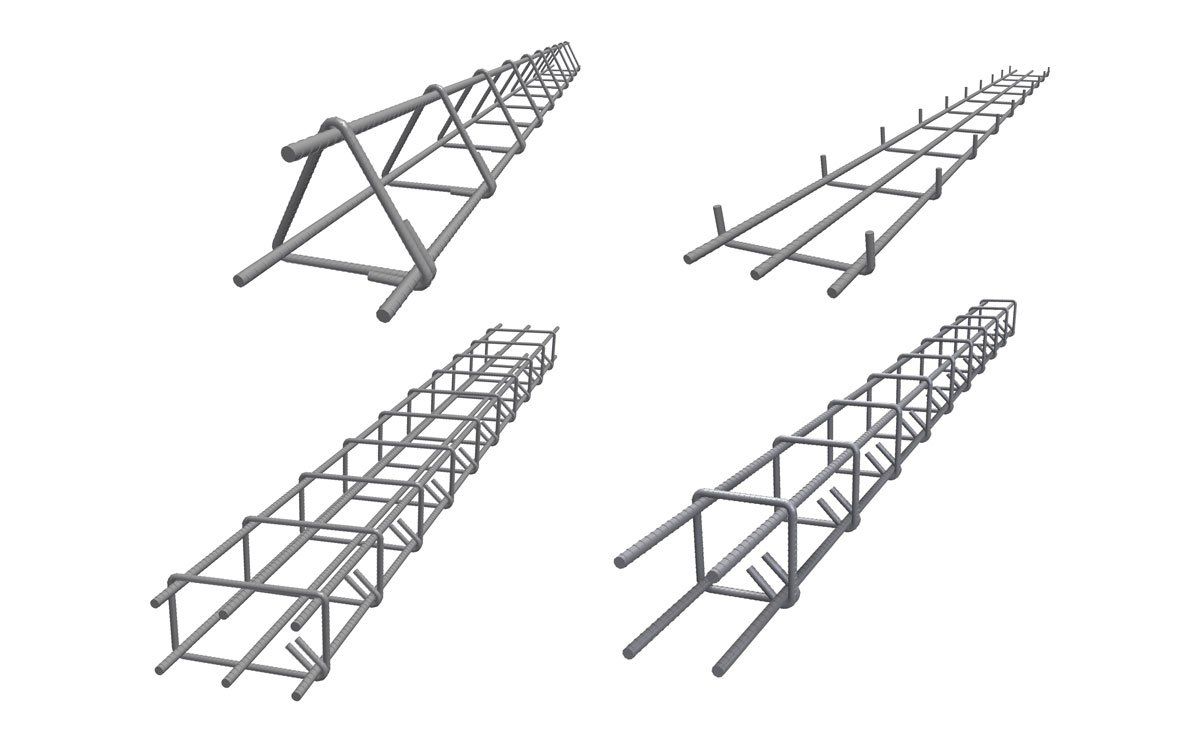

Bending of reinforcement mesh

In combination with the mesh welding machines, an integrated solution is offered with bending of the welded mesh both in-line and off-line.

With the "single" bend system, individual wires in both the periphery of the mesh and recesses can be bent a number of times, which can be used, for example, as interpreted distance stirrups between lower and upper mesh in elements or as rib reinforcement in the sides of the element.

With the line bending system, the entire side of the mesh is bent at one time, e.g. for facade elements rib reinforcement or for reinforcement for columns and beams. Here, too, a robot solution can be offered where everything takes place fully automatically from wire to pre-bent reinforcement solution.